Workplace injuries, accidents, and health issues put organisations under pressure to protect their employees. This is where ISO 45001 for Occupational Health and Safety (OH&S) Management Systems comes into play.

Not only does health and safety affect individuals, but it can also disrupt operations, damage reputation, and carry legal and financial consequences.

By adopting ISO 45001, the internationally recognised standard, businesses can build a proactive approach to health and safety management, making sure their workplaces are safer, there are reduced risks, and improved overall performance.

What is ISO 45001

ISO 45001 - The Standard for Occupational Health and Safety Management

ISO 45001 is a globally recognised standard for Occupational Health and Safety management. The standard provides a comprehensive framework for organisations to improve their safety practices and mitigate risks.

Unlike previous OH&S standards, ISO 45001:2015 was developed with input from over 70 countries, making it a truly global benchmark and standard. It replaces OHSAS 18001, which many organisations had used previously, and aligns more closely with other ISO management system standards such as ISO 9001 (quality), ISO 14001 (environmental) and more.

At its core, ISO 45001 encourages organisations to take a proactive and preventive, risk-based approach to workplace health and safety rather than reacting to incidents after they happen. By following this standard, businesses not only ensure the health and safety of their employees but also comply with legal requirements and ensure a culture of continual improvement.

The history behind ISO 45001

To fully appreciate ISO 45001, it’s useful to understand where it came from.

- Before ISO 45001: Many organisations relied on OHSAS 18001, a British Standard adopted worldwide. While it was effective, OHSAS 18001 lacked the global recognition and harmonisation offered by ISO standards.

- The shift to ISO 45001 (2018): ISO recognised the need for a single international standard. With contributions from global experts, ISO 45001 was released to unify occupational health and safety practices under one robust framework.

- Future developments: ISO 45001 is continually evolving. Future revisions are likely to integrate emerging workplace risks such as mental health, remote working, and digital transformation, ensuring that the standard remains relevant in the changing world of work.

Key benefits of ISO 45001

- Reduced workplace incidents: ISO 45001 helps businesses identify and control hazards, significantly lowering accident rates and creating a safer work environment.

- Cost savings from fewer disruptions: Fewer incidents mean fewer operational disruptions, leading to lower costs associated with downtime, legal fees, and workers’ compensation.

- Enhanced reputation: Adopting ISO 45001 demonstrates a commitment to high safety standards, which can improve your company’s reputation among clients, investors, and prospective employees.

- Higher employee engagement: A strong safety culture makes employees feel valued, increasing morale, job satisfaction, and productivity.

- Improved compliance and efficiency: By providing a structured framework for safety management, ISO 45001 ensures compliance with regulations and promotes smoother, more efficient operations.

Key Terminology in ISO 45001

To work effectively with ISO 45001, here is some key terminology for you to understand.

Below is a sample of some of the terms you will encounter in the standard:

- Hazard: A source with the potential to cause injury, ill health, or damage.

- Risk: The combination of the likelihood of an occurrence of a hazardous event and the severity of injury or ill health that can be caused.

- Incident: Something arising out of, or during, work that could or does result in injury or ill health.

- Worker participation: A fundamental requirement under ISO 45001, ensuring employees are actively involved in safety decisions.

- Continual improvement: The ongoing effort to improve safety performance over time.

Comprehensive knowledge of ISO 45001 terms will empower managers and auditors to implement and communicate safety management effectively. Learn more on how to become an OHS Auditor.

Core elements of ISO 45001:2018

At its core, ISO 45001 encourages organisations to take a proactive and preventive, risk-based approach to workplace health and safety rather than reacting to incidents after they happen.

By following this standard, businesses not only ensure the health and safety of their employees but also comply with legal requirements and ensure a culture of continual improvement.

ISO 45001 is structured around the Harmonised Approach to aid alignment and integration with other ISO Management System standards, like ISO 9001, ISO 14001, and more.

The key elements include:

- Context of the Organisation – Understanding internal and external factors that affect health and safety.

- Leadership and worker participation – Strong leadership commitment and active involvement of employees.

- Planning – Identifying hazards, assessing risks, and setting safety objectives.

- Support – Making sure resources, training, and communication are in place.

- Operation – Establishing processes to control risks and manage change.

- Performance evaluation – Monitoring, measuring, and auditing safety performance.

- Improvement – Corrective actions and continual improvement of the system.

Download our free step-by-step guide “Preparing for ISO 45001 OHS Implementation” to gain practical strategies for safety management within your organisation.

How does ISO 45001 improve Workplace Safety

ISO 45001 offers more than a Health and Safety compliance solution. It assists in creating a sustainable culture of safety management that can be adopted across the entire organisation.

Looking to take your workplace safety to the next level? Read on proven strategies in our article on how to improve your OH&S performance by 50% or more. With practical steps and expert insights, it’s the perfect resource for managers ready to achieve measurable results.

Aligning ISO 45001 with Business Strategy

For ISO 45001 to be fully effective, it must be aligned with your overall business strategy. By aligning safety management with strategy, organisations move beyond compliance and unlock real business value.

- Safety as a business value: Position safety management as integral to long-term success.

- Risk management integration: Incorporate OH&S risks into enterprise-wide risk management.

- Stakeholder confidence: Customers, investors, and regulators view ISO 45001 certification as a mark of trust.

- Competitive advantage: Organisations with ISO 45001 often outperform competitors in tenders and contracts.

Integration of Safety into Business Strategy with ISO 45001

Integrating health and safety into an organisation’s overall strategy is a key principle of ISO 45001:2018. Safety isn’t just a regulatory requirement but a core business priority. ISO 45001 does this by demanding that business risks associated with the OH&S management system are assessed and managed, not only the hazards and risk associated with the workplace.

By aligning safety goals with broader business objectives, companies can ensure a culture where safety becomes a shared responsibility, engaging all levels of the business. Leadership is essential in this integration, as leaders set the tone and demonstrate a commitment to safety that resonates throughout the workforce.

When leaders actively promote safety as a priority, it encourages employees to adopt safe practices, feel empowered to voice concerns, and work collaboratively to identify and mitigate risks.

This strategic alignment not only enhances conformity but also boosts employee morale, reduces absenteeism, and ultimately contributes to a more resilient and productive organisation.

ISO 45001 and Leadership Commitment

Leadership plays a critical role in driving OHS success. ISO 45001 requires top management to:

- Take accountability for workplace health and safety

- Set clear objectives aligned with business strategy

- Provide resources for training, monitoring, and improvement

- Foster a culture of worker participation and consultation

This cultural shift ensures safety isn’t just a policy—it’s embedded into daily decision-making.

Rethinking Risk Management for workplace safety through ISO 45001

Risk as an Opportunity in ISO 45001

Viewing risk as an opportunity can transform a business’s approach to growth, innovation, and safety. Rather than focusing on the dangers alone, forward-thinking companies recognise that calculated risks can unlock rewards in the shape of opportunities.

Take, for example, the aerospace industry. When NASA plans its trips, they are faced with so many unknowns and extreme conditions far away from Earth. Instead of avoiding these risks, NASA’s team assess potential hazards and plan innovative strategies to manage them. From precise landing procedures to advanced robotic controls for navigating Mars’s challenges. This proactive approach allows them not only to minimise dangers but also to push the boundaries of exploration and discovery.

The same can be applied in the business world. Identifying, and managing risks early enables companies to turn challenges into opportunities for improvement and competitive advantage. By viewing risk as a manageable stepping stone, businesses can fuel their growth and success even in unpredictable environments.

Managing Risks and Opportunities with ISO 45001

Here are 4 important tips for managing risks and opportunities:

- Induction training: All new employees need to undergo thorough induction training, so they are immediately aware of the health and safety risks within the workplace.

- Ongoing training: Always invest in employee training to keep skills and knowledge up to date.

- Peer reviews: Implement peer reviews to identify potential risks and assess mitigation strategies before they escalate.

- Document control: Use document control software to manage workflows and ensure that risk assessments are shared and reviewed across the organisation.

Shifting Risk Management Conversations

The shift in risk management thinking from a compliance-driven approach to a value-driven one has transformed how organisations approach occupational health and safety.

Instead of viewing risk simply as something to be minimised or avoided, ISO encourages businesses to see risk management as a valuable way to improve performance.

This means businesses should assess risks not only to avoid accidents and regulatory issues but also to identify opportunities to enhance worker well-being and business efficiency.

By adopting this proactive mindset, companies can turn risk management into a strategic tool that results in safer workplaces, boosts productivity, and strengthens their overall commitment to employee health and safety.

Download our free step-by-step guide “Preparing for ISO 45001 OHS Implementation” to gain practical strategies for safety management within your organisation.

Health & Safety culture with ISO 45001

A management system is only as strong as the culture that supports it. ISO 45001 emphasises the role of leadership and worker involvement in shaping a culture of safety.

- Leadership visibility: Managers must lead by example, demonstrating safety as a priority.

- Open communication: Encourage reporting of near misses without fear of blame.

- Training and competence: Equip staff with the knowledge and skills to work safely.

- Recognition and rewards: Acknowledge contributions to safety improvements.

What is a Safety Culture?

A safety culture is an environment where health and safety practices are embedded in every level of the business. This includes employees actively participating and taking responsibility for both risks and preventive actions.

Rather than viewing safety as a set of rules, a strong safety culture makes it a shared value, driving behaviours that prioritise well-being across the business.

Encouraging employee participation

When workers are involved in safety processes—such as identifying hazards, suggesting improvements, and participating in safety meetings—they feel empowered to take ownership of both risks and solutions.

This involvement not only increases awareness but also leads to better conformance, as employees see safety as part of their job and are more likely to adhere to practices they have helped shape.

How do I engage staff and improve safety performance?

Engagement starts with open communication, where leaders actively listen to employees’ concerns and ideas about safety.

Providing regular training, celebrating safety achievements, and offering opportunities for employees to contribute to safety initiatives can all improve engagement.

With each step we have listed, safety becomes more than a checklist—it becomes a core element of the organisation’s identity, creating a proactive, resilient safety culture.

Measuring safety culture with ISO 45001

One of the most powerful aspects of ISO 45001 is its focus on performance measurement. But how do you measure something as intangible as safety culture? Here are some examples for you:

- Safety climate surveys – Collect employee perceptions on safety attitudes and behaviours.

- Leading indicators – Track proactive measures such as training hours, hazard reports, and near-miss reporting.

- Lagging indicators – Monitor outcomes such as incident rates, lost time injuries, and absenteeism.

- Audits and reviews – Use internal and external audits to gauge system effectiveness.

Challenges in measuring safety culture

Measuring safety culture can be challenging due to its intangible nature as workplace culture. It is largely shaped by attitudes, beliefs, and behaviours that aren’t always easy to quantify.

However, ISO 45001:2018 provides a structured approach to assessing and enhancing safety culture. Practical steps include employee surveys, feedback sessions, and regular safety audits to gauge engagement, perceptions, and participation levels.

While these tools may not directly measure culture, they offer insights into how employees view safety and how embedded safety practices are across the organisation.

6 signs your safety culture is on track

- Open communication – Employees feel safe reporting issues without fear of blame.

- Employee participation – Staff actively engage in safety initiatives and identify hazards or risks.

- Leadership involvement – Leaders demonstrate commitment by supporting and participating in safety efforts.

- Proactive behaviour – Preventive measures are prioritised, with an emphasis on addressing risks before they cause harm.

- Continual improvement – Safety practices are regularly reviewed and updated based on feedback and audits.

- Shared responsibility – All employees, from top to bottom, take ownership of safety.

Download our free step-by-step guide “Preparing for ISO 45001 OHS Implementation” to gain practical strategies for safety management within your organisation.

Leading and Lagging Indicators in Safety Management

Lead versus Lag Indicators and the safety culture link

Tracking safety culture effectively requires both lead and lag indicators.

Lag indicators, like incident rates, provide data on past performance, while lead indicators, such as training completion rates or safety observations, predict future safety trends.

Lead indicators are particularly valuable in gauging proactive safety efforts, helping organisations understand if their culture promotes preventive actions rather than reactive responses. Remember lead indicators should be carefully selected to create the correct behaviour.

Lagging Indicators: What They Measure

Lagging indicators are metrics that track past incidents, such as injury rates, lost workdays, and recorded safety violations. They provide insights into what has already occurred, helping businesses assess the effectiveness of their safety measures in reducing harm.

While these indicators are valuable for understanding historical performance, they have limitations when it comes to future prevention. Because they only capture incidents after they’ve happened, lagging indicators don’t offer proactive insight or guidance on preventing future risks.

Leading Indicators: A Proactive Approach

In contrast to lagging indicators, leading indicators are predictive tools that help organisations proactively manage and reduce safety risks before incidents occur. These indicators track activities such as safety training completion rates, hazard identification efforts, and frequency of safety audits. Lead indicators are also levers to change behaviour. If a person knows they are being measured against a specific attribute, they pay attention to it. Lead indicators should be carefully selected to create the correct behaviour.

By focusing on ongoing, preventive actions, leading indicators help companies identify and address potential hazards early. This forward-looking approach enables a culture of continual safety improvement, guiding teams to focus on preventive measures over reactive responses.

How to effectively implement ISO 45001 in your organisation

Implementing ISO 45001 is not just a compliance exercise, it’s a transformation in how your organisation approaches health and safety. Success relies on leadership, worker involvement, and embedding the standard’s principles into everyday operations.

Steps for Effective Implementation of ISO 45001:2018

Step 1: Leadership Commitment

- Secure top management buy-in.

- Define the OHS policy and align it with business strategy.

Step 2: Gap Analysis

- Compare current practices against ISO 45001 requirements.

- Identify gaps in processes, documentation, and culture.

Step 3: Define Scope and Objectives

- Clarify the boundaries of the OHSMS.

- Set measurable health and safety objectives.

Step 4: Risk and Opportunity Assessment

- Identify workplace hazards, assess risks, and determine opportunities for improvement.

Step 5: Develop Core Processes

- Establish processes for consultation and participation.

- Define emergency preparedness and response plans.

Step 6: Implement Training and Awareness

- Train employees on new procedures and responsibilities.

- Raise awareness of ISO 45001 goals.

Step 7: Documentation and Controls

- Develop required documentation (policies, procedures, records).

- Implement operational controls to manage risks.

Step 8: Monitor and Measure

- Establish performance metrics (leading and lagging).

- Conduct regular audits and reviews.

Step 9: Internal Audit and Management Review

- Verify effectiveness of the OHSMS.

- Engage leadership in reviewing progress.

Step 10: Certification Readiness

- Conduct a pre-certification audit.

- Close identified gaps before external assessment.

Download our free step-by-step guide “Preparing for ISO 45001 OHS Implementation” to gain practical strategies for safety management within your organisation.

Common Challenges and How to Overcome Them

- Resistance to change: Overcome by communicating benefits and involving employees early.

- Resource constraints: Prioritise critical risks and implement improvements in phases.

- Poor communication: Use multiple channels like emails, posters, meetings etc. to keep safety top of mind.

Explore new perspectives to Thinking Differently about Workplace Safety Risks. It’s a fresh take on how organisations can rethink hazards and build smarter safety strategies.

How to Streamline OHS Documentation

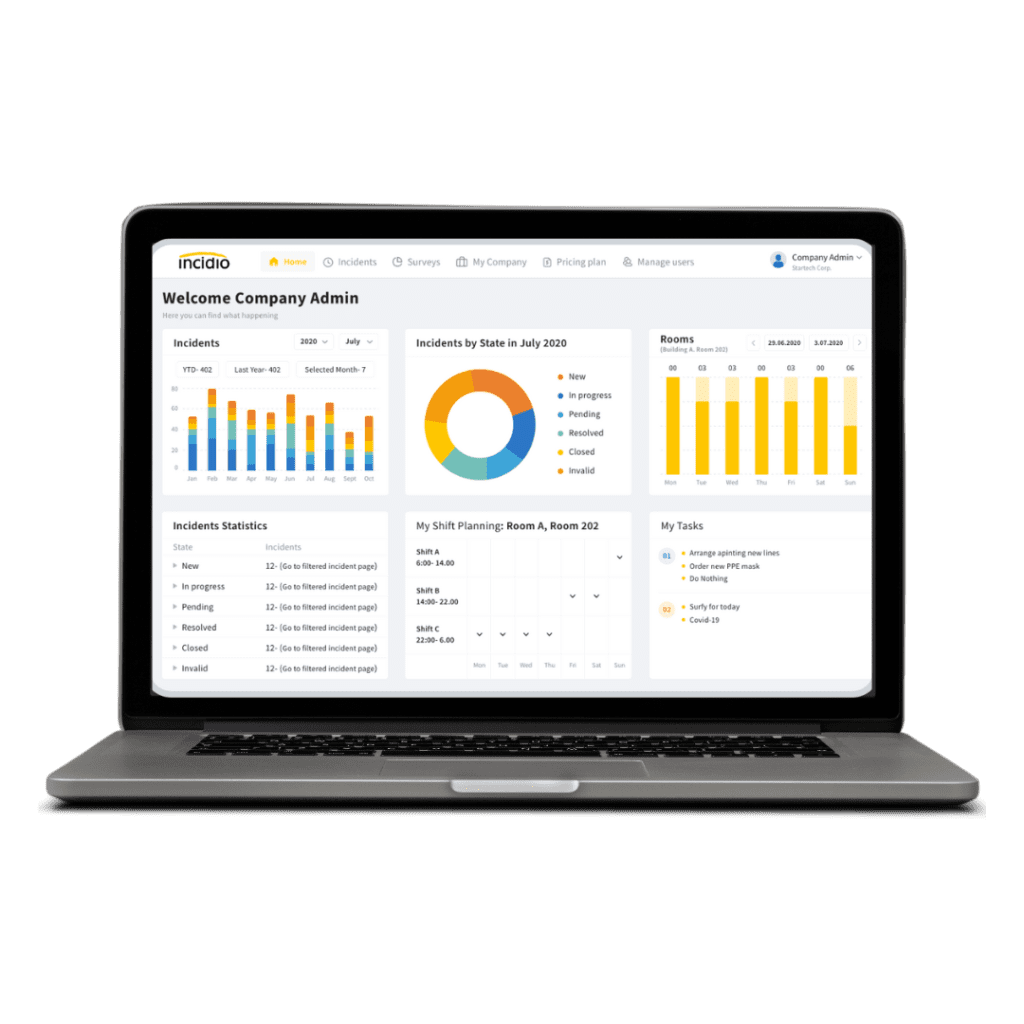

Managing OHS documentation is often admin-heavy. The INCIDIO software suite is a purpose-built GRC platform, designed to simplify ISO management systems.

INCIDIO automates your management system, from risk management and document control to incident reporting and analytics. It also directly supports the requirements of Clause 7.5 and beyond.

Outcomes you can count on:

- Version Control: Automatic logging of approvals, edits, and archiving

- Audit-Ready Logs: Generate compliance reports instantly

- Role-Based Access: Ensure the right people have the right access

- Clause Mapping: Link documents directly to ISO 45001 requirements

- Centralised Access: Consolidate OHS policies, incident reports, and training records

Choose the deployment that fits your environment

INCIDIO365 (for Microsoft 365 / SharePoint users)

Native SharePoint integration; works with Teams, Outlook and OneDrive.

Uses your existing identity and permissions for seamless access control.

Familiar UI for fast adoption across sites and departments.

Explore the INCIDIO365 add-on, built to seamlessly integrate with your Microsoft SharePoint environment. Perfect for organisations wanting to keep streamline their ISO Management System within existing Microsoft infrastructure.

INCIDIOcom (cloud-native, platform-agnostic)

Standalone SaaS for multi-site, multi-standard document control.

Scales quickly without relying on your Microsoft stack.

Ideal when you need a single source of truth across varied operations.

INCIDIOcom software solution helps organisations manage ISO Management System requirements more effectively. This is ideal for businesses not currently using Microsoft SharePoint.

Join a software-automation demo session

If you’ve been considering how to digitise and streamline your management system, these upcoming live demo sessions are the perfect opportunity to see INCIDIO in action.

Why join a Demo Session?

- Live walkthrough of key features

- Opportunity to ask questions directly to our product experts

- Practical tips on digitising your ISO system without unnecessary complexity

Seats are usually limited, so be sure to secure your spot early and take the first step towards a smarter, more resilient management system.

How does ISO 45001 Certification work?

Certification provides independent verification that your OH&S management system meets ISO 45001 requirements.

The process usually involves:

- Application and contract – Select an accredited certification body.

- Stage 1 Audit – Review of documentation, policies, and planning.

- Stage 2 Audit – On-site assessment of implementation and effectiveness.

- Certification decision – Issuance of the ISO 45001 certificate if compliant.

- Surveillance audits – Regular audits to ensure ongoing compliance.

- Recertification – Every three years, a full audit is required to renew certification.

Certification validates your management system and improves stakeholder confidence in your commitment to safety.

Why does ISO 45001 Matter?

ISO 45001:2018 is more than just a conformity tool, it is a management system that helps businesses proactively identify and address health and safety risks. By implementing ISO 45001, companies activate a a strategic advantage as they can ensure the health and safety of their employees, comply with regulations, and ensure a safety culture that leads to continual improvement.

To achieve success with ISO 45001, organisations must follow a structured implementation process, engage leadership and employees, and focus on ongoing training, risk assessments, and audits. In doing this your business will not only protect its most valuable asset, which is its people, but also position itself for success in a competitive, safety-conscious market.

Enhancing Occupational Health and Safety with ISO 45001 is about creating safer, healthier, and more resilient workplaces.

By focusing on risk reduction, leadership, and worker participation, organisations can prevent incidents, boost performance, and build trust with employees and stakeholders.

Download our free step-by-step guide “Preparing for ISO 45001 OHS Implementation” to gain practical strategies for safety management within your organisation.

Get Started with iso 45001 today

Whether you’re starting from scratch or migrating from OHSAS 18001, ISO 45001 can seem daunting. However, with the right support, it can be a smooth and rewarding journey.

How does Risk Group work with ISO 45001?

With over 30 years of experience, Risk Group supports organisations of all sizes across the EMEA region in implementing, auditing, and maintaining ISO 45001 Management Systems. Our experts guide you from initial gap analysis through training to certification support.

We offer specialised that include (but are not limited to) ISO management training, consulting, and risk assessment services, extending a variety of ISO 45001 training options tailored to your requirements.

For more information on how we can help your organisation achieve ISO 45001 certification, contact us at +27 (0) 31 569 5900 or enquiries@riskgroup.ltd.

Like what you read? Share this blog post on your preferred social media platform: